Sani-Matic’s Process Tanks are meticulously engineered to meet the stringent demands of sanitary and hygienic industries, including food, beverage, personal care, and biopharmaceutical sectors. Manufactured in Sun Prairie, Wisconsin, these tanks are available in standard sizes ranging from 135 to 1,075 gallons, ensuring quick turnaround times without compromising quality.

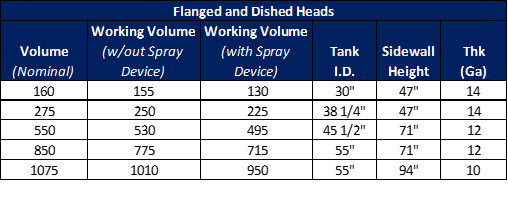

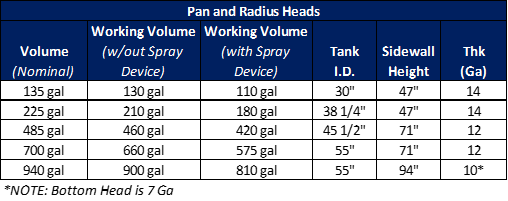

Standard food and beverage grade tanks are detailed below and available in two tank head variations – Pan & Radius Heads or Flanged & Dished Heads. The tank heads listed below are the Sani-Matic standard process tank sizes. Custom sizes are available upon request.