Industry: Commercial Baking & Food Production

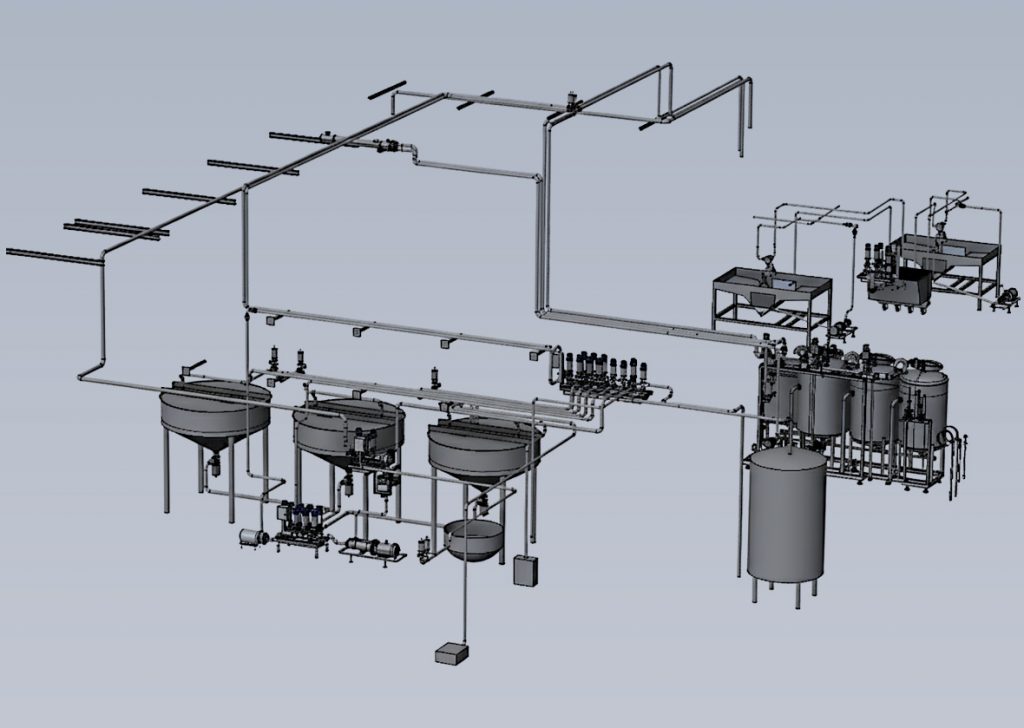

Solution: Custom CIP System with Mixproof Valves and Data Collection

Results: 50% reduction in cleaning time, increased daily production capacity

The Challenge

A commercial bakery was working with outdated cleaning equipment and limited data capabilities, making it challenging to meet evolving product needs.

Their biggest problems:

- Labor-intensive manual cleaning process.

- Inconsistent cleaning: residue left in process piping and tanks.

- Production delays due to lengthy cleaning cycles.

- Outdated instrumentation with limited data visibility.

The facility needed a modern, automated solution that could improve sanitation without interfering with production.

The Solution

Oliver M. Dean, in partnership with Sani-Matic, designed a comprehensive Clean-in-Place (CIP) system that transformed operations on multiple levels:

Automated Cleaning System

- A local control panel with fully functional operator screens reduced manual labor significantly.

- Cleaning cycles were shortened considerably while maintaining consistent results.

- Reliable data capture supported by digital recordkeeping.

Production Optimization

- Alfa Laval mixproof valves enabled tank cleaning while simultaneously running production in another.

- Twin screw pumps were sized for both production and CIP cycles.

- Existing tanks were repurposed to eliminate the need for separate production areas.

Comprehensive Specifications

The project required adherence to detailed specifications covering everything from materials of construction to CIP programming. Oliver M. Dean met corporate standards while maintaining the project budget.

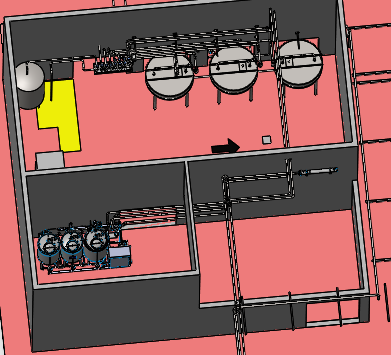

Implementation

Zero-Downtime Approach

- All work completed on weekends and off-hours.

- Equipment staged in on-site containers for organized execution.

- Commissioning executed in phases across key production areas.

Collaborative Management

- Regular stakeholder meetings kept the project moving.

- Successfully navigated scope of work changes without delays.

- Digital-first approach with all drawings reviewed electronically.

The Results

Immediate Impact

- Cleaning time reduced by 50%.

- Increased flexibility in cleaning and production scheduling.

- More consistent sanitation performance.

Long-Term Benefits

- Enhanced compliance with comprehensive data collection.

- Scalable foundation to support future product lines.

- Improved system reliability.

The Conclusion

This project shows how automation can enhance cleaning consistency, boost production time, and simplify compliance, without slowing down operations. Oliver M. Dean delivered a solution that met demanding specifications and created room for scalable growth through collaboration.

Clean Faster. Produce More. Stress Less.

Discover how our hygienic automation solutions can cut sanitation time and help you scale production. Book a free consultation today.