Industry: Prepared Foods

Solution: Automated Hot Water Batching System

Results: Increased daily batch output and system efficiency

The Challenge

A food processor was experiencing delays in production due to an inefficient ingredient batching system. The process involved filling kettles with cold, treated city water, which then had to be heated within the kettle using live steam injection or a steam jacket. This not only slowed down production but also wasted energy, as steam used in direct injection could not be recovered and returned to the boiler.

Each batch required operators to wait for the water to reach temperature before they could begin cooking. This bottleneck was directly limiting the number of batches that could be produced in a day. The facility needed a way to reduce in-kettle heating time and increase overall throughput without disrupting daily operations.

The Solution

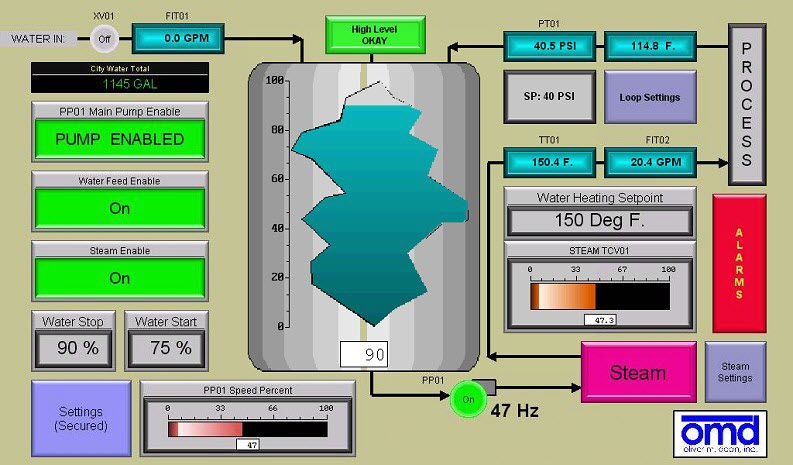

The facility upgraded its process with a new hot water addition to the existing automated batching system. The new system feeds 12 kettles and was designed to deliver hot water on demand at a preset temperature, eliminating the need to heat water inside the kettle and dramatically reduce batch prep time.

Key components included:

- Enerquip shell-and-tube heat exchanger for instantaneous water heating.

- Alfa Laval LKH centrifugal pumps to keep water moving efficiently through the closed-loop system.

- Burkert globe valves and IFM instrumentation to regulate flow and maintain precision throughout the process.

In addition, Oliver M. Dean developed a custom automation platform that allows the hot water system to communicate directly with the batching system. This integration ensures that hot water is only sent when requested, improving coordination between systems and preventing energy waste.

About 700 feet of sanitary piping was installed, with work scheduled after hours and on weekends to avoid downtime. The final system startup was completed in under a week.

The Results

The new ingredient batching system significantly improved the facility’s production capabilities:

- Reduced Batch Turnaround Time: Operators no longer need to wait for water to heat inside the kettles. With pre-heated water delivered directly, each batch starts faster, resulting in more batches per day.

- Increased Energy Efficiency: The closed-loop system captures and recycles energy, making better use of the plant’s steam resources and reducing overall consumption.

- Positive Feedback: The facility’s team was extremely satisfied with the outcome, noting that the project “was run really well” and the system has been “running flawlessly” since implementation.

The Conclusion

This targeted upgrade to the automated batching system helped the food processor overcome a major production bottleneck. By enabling instant hot water delivery and eliminating in-kettle heating delays, the company increased daily output and reduced energy use – all without interrupting normal operations. The results have laid a solid foundation for future process improvements at the plant.

Want Results Like These?

Facing similar production bottlenecks? Our team can help. Schedule a complimentary on-site consultation with an OMD expert to identify opportunities for improvement in your batching system.