LAUFER DMV Product Recovery Systems are designed to recover high-value product, reduce waste, and maintain the highest hygienic standards in sanitary process lines. Built for applications handling viscous or fast-hardening media such as yogurt, dressings, chocolate, or toothpaste, these systems streamline production while reducing cleaning time and wastewater generation.

Each system features 3-A certified LIAG® Free Flow Arc Valves and precision-engineered product recovery components designed without dead pockets. The modular construction minimizes threads and clamp unions, eliminating typical hygienic risk areas. Even when welded in place, LIAG® valves can be easily disassembled for maintenance, ensuring long-term reliability and compliance with sanitary requirements.

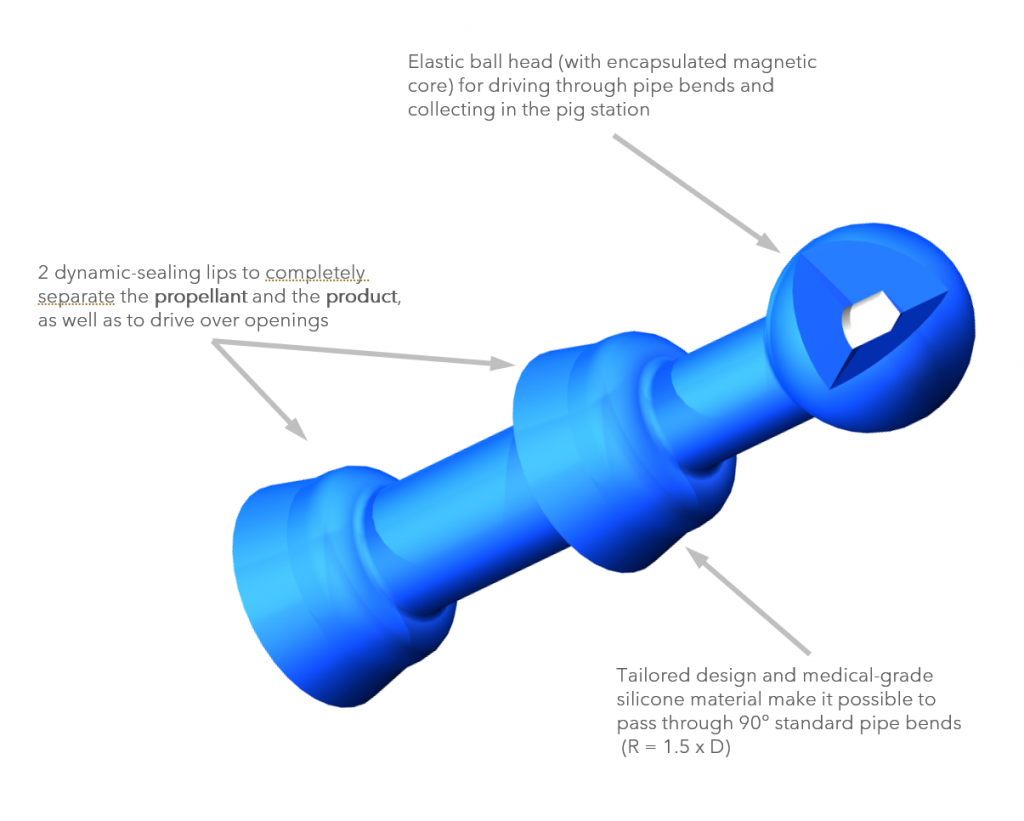

The DMV system operates with a two-seal dynamic lip pig made from FDA-compliant silicone. Its flexible, homogeneous design provides a secure seal against the pipe wall while adapting to minor variations in pipe geometry. The pig passes standard 90° bends (R = 1.5 × D) and can be fitted with an encapsulated magnet for location and control.

Each product recovery system is custom-engineered for its process environment. LIAG® launching and receiving stations ensure sterile, closed operation and optimized cleaning performance. Dynamic DMV lip pigs maintain consistent hygiene and enable efficient recovery of product between cleaning cycles.

Each product recovery system is custom-engineered for its process environment. LIAG® launching and receiving stations ensure sterile, closed operation and optimized cleaning performance. Dynamic DMV lip pigs maintain consistent hygiene and enable efficient recovery of product between cleaning cycles.

System Advantages