Industry: Dairy & Beverage

Solution: Custom CIP-Ready Powder Mixing System with Valves

Results: Reduced footprint, improved blending, easier maintenance, and enhanced SQF compliance

The Challenge

A major dairy customer with in-house beverage production faced challenges with outdated mixing equipment used in products like teas and chocolate milk. Their legacy system had:

- Frequent maintenance issues requiring extended downtime

- Inconsistent powder blending, impacting product quality

- An oversized footprint that limited ingredient storage and workflow

- Manual powder addition methods that complicated operations and SQF compliance

The system also required operators to leave doors open during processing, conflicting with SQF sanitation standards.

The Solution

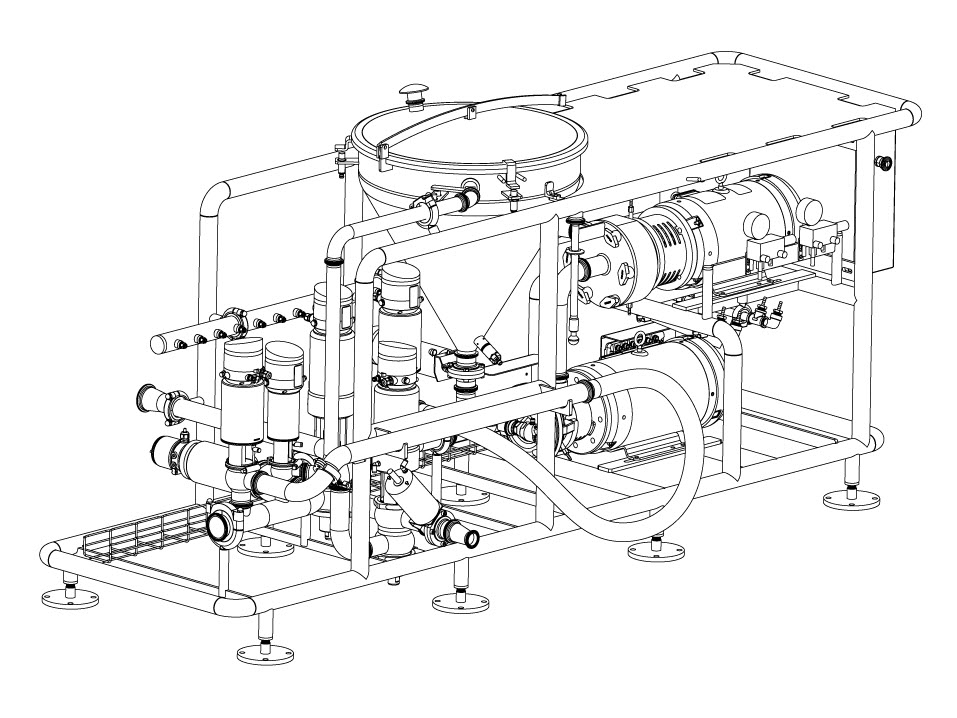

Oliver M. Dean designed and delivered a custom sanitary mixing system tailored to the brand’s specific needs. The upgraded solution included:

- A compact Ampco POWDER-max powder mixer with a smaller footprint, eliminating the need for a platform and allowing full ingredient pallet access with doors closed

- A self-priming liquid ring pump for efficient drum suction—removing the need for diaphragm pumps

- A shear pump to deliver consistent, high-performance blending

- A tabletop powder hopper, improving operator ergonomics and safer powder handling

- Two mixproof valves, enabling clean, automated liquid ingredient integration (such as liquid sugar)

- Fully CIP-capable system, eliminating manual cleaning and reducing downtime

The design also ensured every component—from valving to suction—was cleanable without disassembly.

The Results

- Improved blending performance, reducing reliance on stabilizers

- Fully CIP-ready, with no manual cleaning needed

- Faster, cleaner drum suction—2–3 minutes without additional pumps

- Streamlined operations, with simplified maintenance and fewer wearable parts

- Improved SQF compliance, thanks to a compact system and closed-door processing

The Conclusion

By replacing outdated equipment with a custom sanitary powder mixer system, Oliver M. Dean helped this dairy customer improve product quality, reduce operational strain, and maintain strict food safety standards.

Want Results Like These?

We help dairy and beverage manufacturers design hygienic, high-performance systems that improve product consistency, reduce downtime, and support regulatory compliance.